One of Scotland’s innovation centres is working with St Andrews University on new screen technology that will reduce the reliance on rare earth metals.

CENSIS – the centre for sensing, imaging, and Internet of Things (IoT) technologies – is working with spinout company SolOLED to develop more sustainable materials for screens used in TVs and smartphones.

The company has secured a £200,000 funding grant to further its work on an alternative to the metal iridium, which is found in organic light-emitting diodes (OLEDs) used for screens.

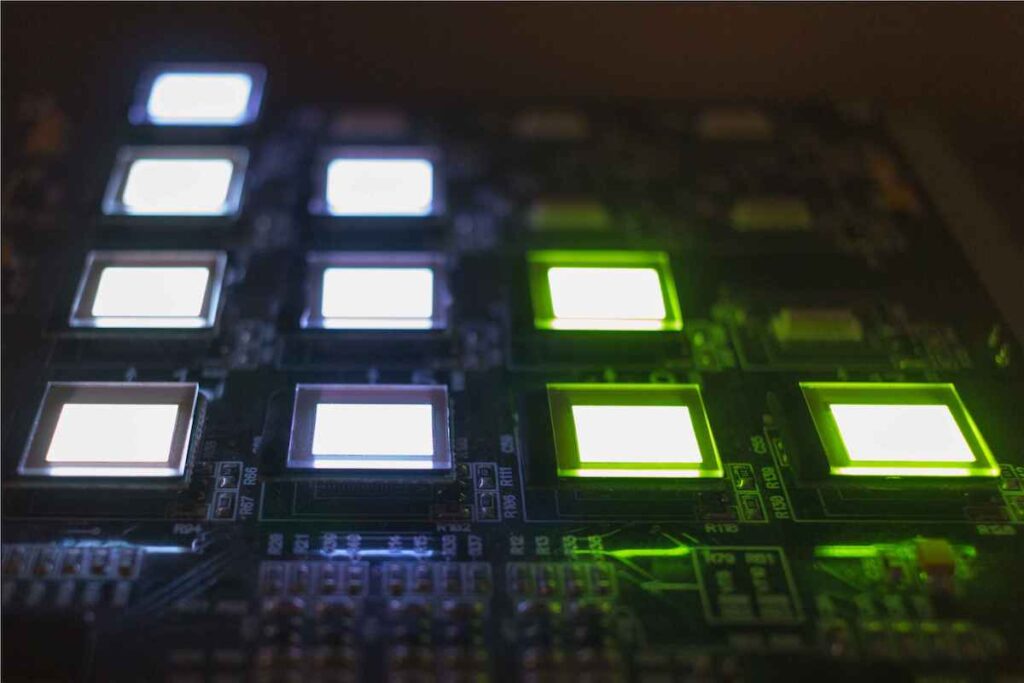

Like traditional LEDs, OLEDs produce light when an electric current passes through them, the colour of which is linked to the nature of the emitter material used. Current solution-processed green and red OLEDs employ emitters that contain the scarce, environmentally impactful, and costly noble metal iridium.

OLEDs are rapidly replacing traditional LED and liquid-crystal display (LCD) technologies and are used in a variety of technologies that are becoming increasingly ubiquitous in modern life – including smartwatches, mobile phones, and TVs. They will also be key components of more flexible, large area, and interactive technologies, such as VR headsets and transparent touch screens, in the future.

The global market for OLEDs is expected to expand significantly over the next few years, with the OLED panel market alone predicted to grow by 12.9 per cent annually from 2021 to 2026. Solution-processed OLEDs currently represent a small but rapidly growing segment of overall OLED sales and the market for the materials that are used in solution-processed OLEDs is projected to have a year-on-year growth of around 145 per cent.

Eli Zysman-Colman, CEO of SolOLED, said: “The market for solution-processed OLEDs is growing apace and will need new and improved performance materials to feed its supply chains. We believe we are the first company to be dedicated to developing sustainable materials that can replace the scarce, noble metals presently used in solution-processed OLEDs. While they have different physical properties, the materials have similar performance characteristics, but with the added benefit of being much cheaper and more sustainable than the compounds that contain iridium.

“Although the concept behind our materials has existed for decades, its relevance to OLEDs has only really been put into practice in the last ten years. Our specific focus is on developing emitter materials for solution-processed OLEDs. The next step is to commercialise these materials and the project with CENSIS and funding from Scottish Enterprise will help in this endeavour. We are still early in the process, and we have a variety of events coming up this year where we can demonstrate the technology and showcase it to potential investors and customers.”

Natalia Lukaszewicz, business development manager at CENSIS, said: “SolOLED’s materials could be revolutionary for the global solution-processed OLED market. The sustainability benefits are potentially huge, removing the need to mine scarce, precious metals that typically underpin emitters. In turn, this could have a significant impact on the cost of producing a range of everyday technologies, as well as a broad range of other applications in the future. This project underlines the quality and commercial potential of the research being undertaken in Scotland’s world-class universities, which we aim to unlock with our industry knowledge and connections.”

The novel approach involves developing a family of novel ‘organic thermally activated delayed fluorescence’ (TADF) dendrimers that are sustainable and more cost-effective to synthesise and show comparable performance in solution-processed OLEDs to commercial metal-based emitter.