A Scottish college has invested over £400,000 on a range of equipment to create a “realistic” training environment for manufacturing students and enable them to learn cutting-edge industry techniques.

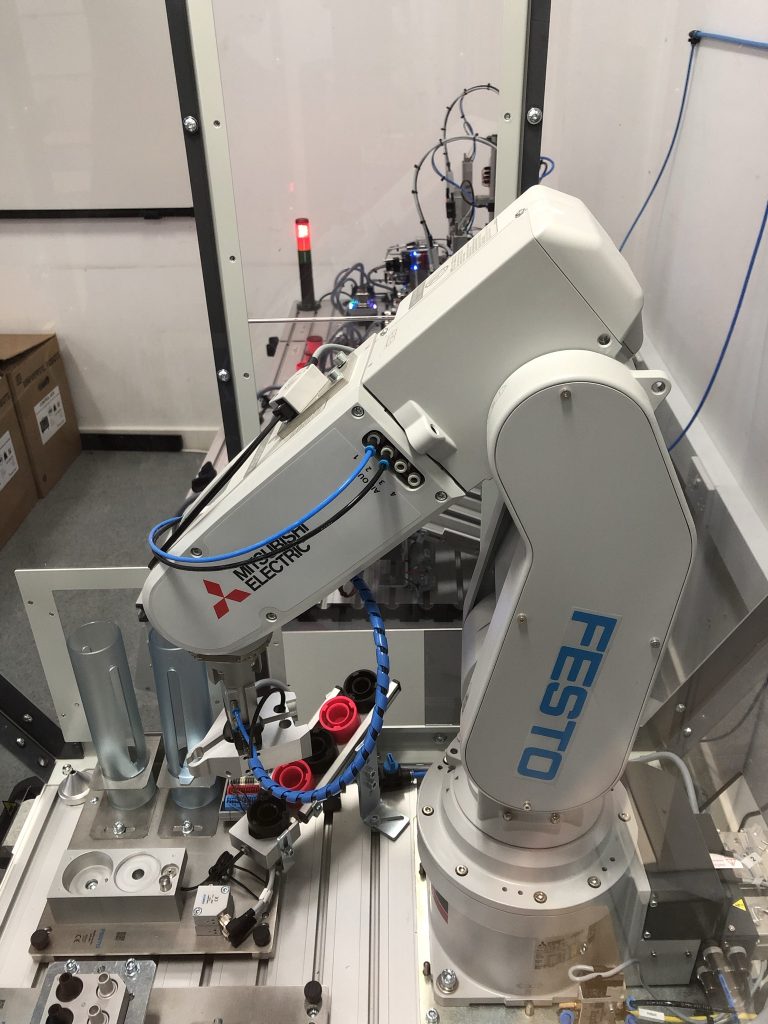

Fife College purchased the machinery from German automation company Festo, one of the world’s leading suppliers of high-quality factory-based production line technology.

The kit includes the most up to date industry technologies, covering pneumatics – a branch of engineering that makes use of gas or pressurised air – hydraulics, robotics and programmable logic controller (PML) – an industrial computer that has been adapted for the control of manufacturing processes.

Each machine is modelled on industry standard production lines, creating “a realistic, relevant, and high-quality training environment for students” who will be prepared to work in “the most modern factories in the world”.

The equipment will help teach students about automation processes such as pick and place, testing and quality inspection, workpiece processing, workpiece sorting, robotic assembly and workpiece storage and retrieval.

Fife College, the ‘first’ in Scotland to purchase such a “significant range” of kit for students, has had to redesign its building in order to fully install it.

The purchases were part of the institution’s drive to increase science, technology, engineering and mathematics (STEM) skills in the region and address the needs of the manufacturing industry as it moves towards smart factories.

Stephen Ayton the academic head for engineering, science, mathematics and STEM at Fife College said: “This new investment illustrates just how committed Fife College is to providing the very best learning experience for our students.

“We want to make sure anyone studying manufacturing with us learns about the latest techniques that are being used in the industry, so that they’re equipped with the skills needed to work in any modern factory. It’s required a lot of hard work and effort to get the equipment installed, but I’m delighted that we’re the first college to offer this wealth of experience to our students.

“This forms a part of our drive to increase STEM skills in the Fife region and to ensure that we meet the digital needs of this ever-evolving industry. The digitalisation and automation of manufacturing processes is evolving all the time, and thanks to this new technology our students will be work ready for industry.”

Kayleigh Ferguson, an academic and quality manager at the college who has been using the equipment said: “This equipment showcases the latest technology in the manufacturing industry, and it’s been great to be able to introduce our students to it. Learning about this machinery and the manufacturing processes they are used in will provide them with the knowledge and skills to work in the most modern factories in the world.

“They’ve all really enjoyed having a chance to operate this equipment, and I’m looking forward to introducing more of our students to it over the coming months.”